|

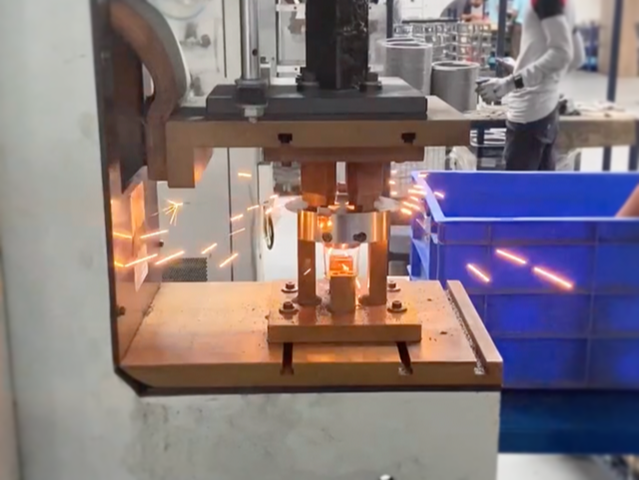

Sheet metal stamping, where progressive and stage tools with autoloaders are used to achieve the high precision needed to manage an ethanol flame

|

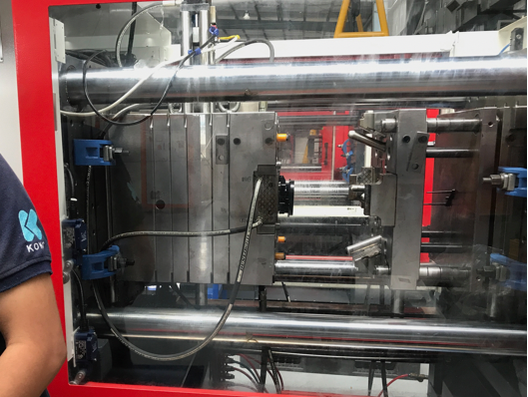

Injection moulding, where engineering-grade plastics are custom-moulded to cater to ethanol distribution

|

Powder coating, where heat and ethanol-resistant custom powder is used before the cooker is cured in a camel-back oven

|

Large scale manufacturing processes were customized to ensure minimum cycle times

|

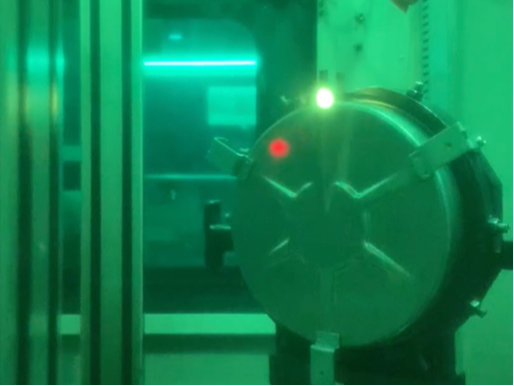

At the heart of the factory is a state-of-the-art toolroom. This toolroom is capable of full-scale development as well as high-quality tool maintenance that can increase tool life and deliver sustained output. The toolroom also supports the design, development and upkeep of fixtures, jigs and gauges across the shop floor.

|

Quality control and continuous improvement

Considering the nature of the product, the quality of each part is vital to ensuring that KOKO customers have a positive experience. Each part is therefore subject to rigorous testing, and undergoes a series of in-line quality checks to ensure that it meets the highest quality standards.

Specific critical parts are also regularly submitted to accredited labs, where they undergo tests.

|

Excellence in execution

|

KOKO is determined to ensure we only produce the best quality products for our customers. Through highly capable processes, quality controls and stable toolings, KOKO Manufacturing generates world-class quality yield that consistently exceeds customer expectations. KOKO Manufacturing is also ISO 9001:2015 certified and has met the required criteria for excellence set by the Kenya Bureau of Standards (KEBS).

Our rigorous quality checking starts before production even begins. Every single part produced in the factory goes through a CTQ (Critical To Quality) dimensional analysis. Before starting a production batch, parts are submitted for CTQ. It is only after the part clears the assessment that batches are produced. KOKO’s expertise and knowledge has resulted in a shift in how quality is approached. KOKO Manufacturing now focuses on quality assurance, where processes and systems are defined that ensure high-quality requirements will be fulfilled. This is a distinct shift from quality control, which focused more on inspection and management of the quality during production. Once our cookers clear our internal assessments, the cookers remain sealed and untouched through their journey through various ports and logistics channels, until it is received by the end customer. |