Clean energy revolution

Building a sustainable cooking solution

Making bioethanol cooking fuel an affordable alternative to dirty fuels

Despite decades of well-intentioned public sector initiatives, most households in sub-Saharan African cities continue to cook with deforestation-based charcoal. Charcoal consumption drives 2 million hectares of deforestation per annum and has wiped out a third of Africa’s natural forest cover over the last 30 years, leading to soil erosion, microclimate change, and worsening food security. and also delivers 1 billion tons of greenhouse gas emissions.

In late 2019, KOKO launched an ambitious new cooking solution in Nairobi aimed at out-competing dirty cooking fuels. KOKO's low-cost two-burner cookstove that runs safely and efficiently on liquid bioethanol reimagines the supply chain, offering consumers a compelling reason to end dirty fuel use. The KOKO customer experience is modern, clean, ultra-safe and delivers material savings to household budgets.

In late 2019, KOKO launched an ambitious new cooking solution in Nairobi aimed at out-competing dirty cooking fuels. KOKO's low-cost two-burner cookstove that runs safely and efficiently on liquid bioethanol reimagines the supply chain, offering consumers a compelling reason to end dirty fuel use. The KOKO customer experience is modern, clean, ultra-safe and delivers material savings to household budgets.

|

Version 6 of the KOKO cooker is a culmination of over 5 years of intensive product development, to create a unique appliance that meets the needs of our consumers across international markets.

The cooker balances performance, efficiency, safety and user-friendliness. |

8 key features that make the KOKO Cooker special are:

|

2,000 W, two-burner cooker that allows greater flexibility in cooking

Vertical Divider

|

Sturdy pot supports that can hold both large and small pots used by consumers, with a flame protecting steel cone

Vertical Divider

|

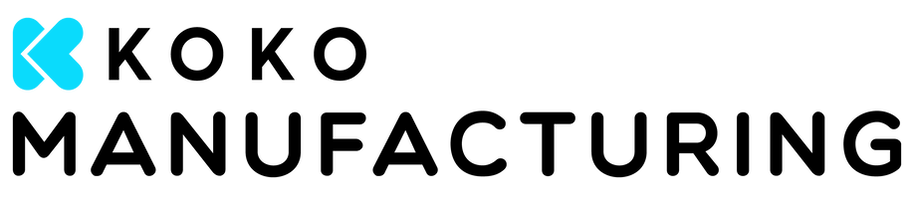

All fuel stays soaked in the ceramic wool burners, enclosed by stainless steel, which ensures that no liquid fuel is ever on the cooker

Vertical Divider

|

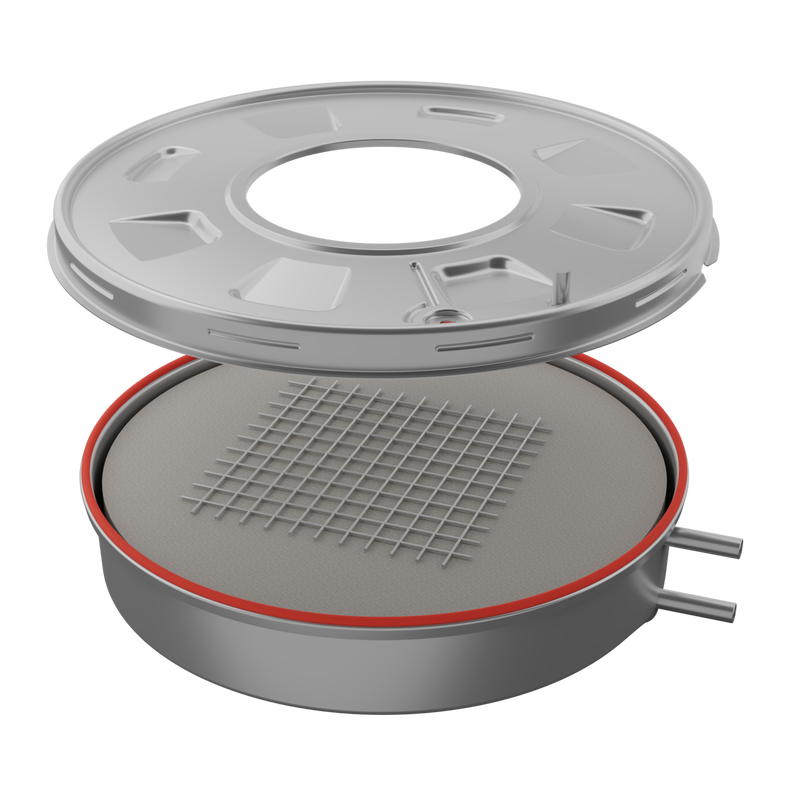

Fully vapour-tight transfer of fuel, preventing any user contact with ethanol at any point in the refill journey

|

|

A ‘SmartValve’ mechanical lock ensures the user cannot turn on the cooker during refill

Vertical Divider

|

Specially-designed ethanol- and heat-resistant powder coating ensures body temperatures do not rise above 40°C

Vertical Divider

|

High-grade SS-304 stainless steel is used for all parts in contact with ethanol fuel or flame

Vertical Divider

|

NFC-tagged canisters that allow KOKO to identify customer accounts and track usage during refilling at the KOKOpoint

|